The debate between Siemens and Eaton has long been a focal point for engineers, electricians, and project managers. Both brands are industry titans with decades of expertise in electrical components like circuit breakers, switchgear, and automation systems. While Siemens and Eaton dominate high-end markets, their premium pricing often leaves budget-conscious buyers seeking alternatives. In this guide, we’ll explore their strengths, limitations, and how CNC Electric offers a practical balance of affordability and reliability for everyday projects.

Siemens vs. Eaton: Key Differences

Before diving into CNC Electric, here’s a quick overview of Siemens and Eaton:

Siemens (Germany)

Pros:

Global Reputation: Trusted for mission-critical infrastructure (e.g., data centers, hospitals).

Cons:

Premium Pricing: Often 10–20% higher than competitors.

Long Lead Times: Custom orders can take 8–12 weeks.

Eaton (USA)

Pros:

Balanced Performance: Reliable mid-tier solutions for commercial and residential use.

Cons:

Limited High-End Features: Lacks advanced smart grid or explosion-proof certifications.

Proprietary Systems: Some components require Eaton-specific panels or tools.

Where Siemens and Eaton Excel

Both brands are unmatched in specialized scenarios:

- Critical Infrastructure: Siemens’ IoT-enabled breakers in data centers or Eaton’s surge protectors for telecom towers.

- Harsh Environments: Siemens’ marine-grade panels or Eaton’s oil-and-gas certified switches.

- Regulatory Compliance: Their products often set the benchmark for global safety standards.

However, for many residential upgrades, small businesses, or non-critical industrial projects, their premium pricing may not align with budget realities

CNC Electric: A Cost-Effective Alternative

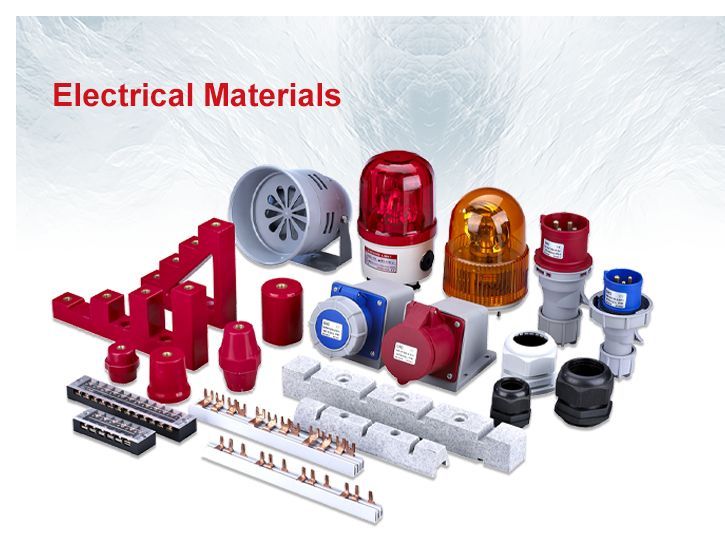

While Siemens and Eaton remain leaders in niche markets, CNC Electric focuses on delivering certified, no-frills electrical components that meet core safety standards at accessible prices.

1. Affordable Reliability

Cost Savings: CNC’s circuit breakers, MCBs, and surge protectors are priced 20–35% lower than Siemens/Eaton equivalents.

Core Certifications: Meets IEC 60898 (residential) and IEC 60947 (industrial) standards.

Simplified Solutions: Ideal for retrofits, solar setups, or small-scale commercial projects.

2. Practical Applications

CNC components are best suited for:

Residential Panels: Upgrading home circuits without overspending.

Renewable Energy: Solar inverters, EV chargers, and off-grid systems.

Emerging Markets: Cost-sensitive projects in regions with unstable grids.

Choosing the Right Brand for Your Project

Prioritize Safety: Always opt for certified products, whether Siemens, Eaton, or CNC.

Assess Project Scope:

High-Risk/High-Tech: Siemens or Eaton.

Budget-Conscious: CNC Electric.

Consider Long-Term Costs: CNC’s warranties and repair affordability add value for small businesses.

Real-World Example: A Balanced Approach

A school in Kenya used Siemens panels for its main grid connection but chose CNC MCBs for classroom circuits. The result? 20% cost savings on the project without compromising safety

Siemens and Eaton set the gold standard for innovation and reliability, and their expertise is irreplaceable in high-stakes environments. However, for everyday electrical needs, CNC Electric provides a practical, budget-friendly alternative that respects the importance of quality and compliance. By focusing on core safety and affordability, CNC empowers homeowners, small businesses, and developing communities to achieve reliable power without overspending.

Post time: Mar-12-2025

Projects

Projects.jpg) Solutions

Solutions Services

Services News

News About Us

About Us